Customer advice and support

WCF advises all customers on design and material selection as well as on the optimal manufacturing process. This is done nationally and internationally.

Worldwide delivery

For most companies, a globalised world poses an enormous challenge. We also guarantee on-time delivery at good conditions to our customers outside Europe. WCF will not shy away from any new challenge across state borders.

Construction

All components to be supplied are designed by WCF in 3D. Solidworks is used for this. Customer records can be processed in the most common formats, such as: .igs, .step, .dwg, .dxf

Model making

For production of WCF components, pattern equipment of all quality levels and materials are used, such as: Wood, plastic or metal.

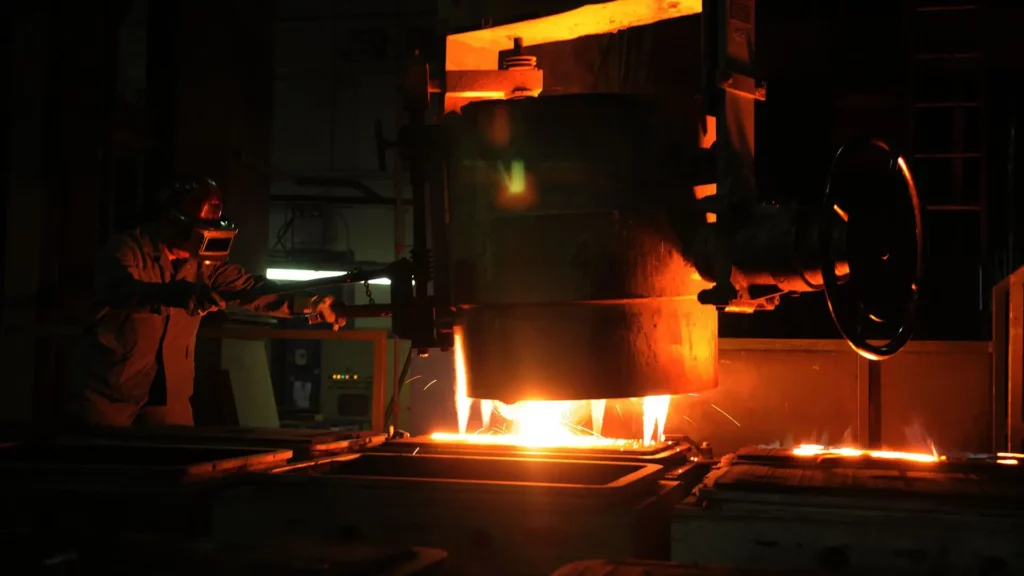

Manufacturing process

WCF supplies components made from investment casting (lost wax process), green sand casting machine- and hand-moulded, centrifugal casting, hand mould casting in the cold resin process and lost mould.

Vertical range of manufacture

WCF supplies raw castings and pre-machined components, as well as finished machined components. Individual components from the individual manufacturing processes can be welded together to form complex components.

Quality assurance

Before the goods are delivered to WCF, inspections such as VT inspection, dimensional inspection, PT inspection, MT inspection, as well as an X-ray can be carried out. For documentation and traceability, reports and certificates about the examinations are produced.

Materials

WCF supplies all common materials, such as: Grey cast iron, nodular cast iron, unalloyed, low-alloyed and high-alloyed cast steel and special materials such as cobalt-based and nickel-based materials.